Nvidia says it has discovered a method to pace up a computation-limited step within the chipmaking course of in order that it occurs 40 instances as quick as right this moment’s commonplace. Known as inverse lithography, it’s a key instrument that permits chipmakers to print nanometer-scale options utilizing gentle with an extended wavelength than the dimensions of these options. Inverse lithography’s use has been restricted by the large measurement of the wanted computation. Nvidia’s reply, cuLitho, is a set of algorithms designed to be used with GPUs, turns what has been two weeks of labor into an in a single day job.

The expertise “will permit fabs to extend throughput, scale back their carbon footprint, and set the foundations for 2-nanometer [manufacturing processes] and past,” mentioned Nvidia CEO Jensen Huang on the Nvidia GTC developer convention on Tuesday.

Main logic-chip foundry Taiwan Semiconductor Manufacturing Co. (TSMC) will likely be qualifying cuLitho’s use in manufacturing beginning in June, mentioned Huang. Design automation software program agency Synopsys plans to combine software program, too, and lithography gear maker ASML plans to help cuLitho in its merchandise as effectively.

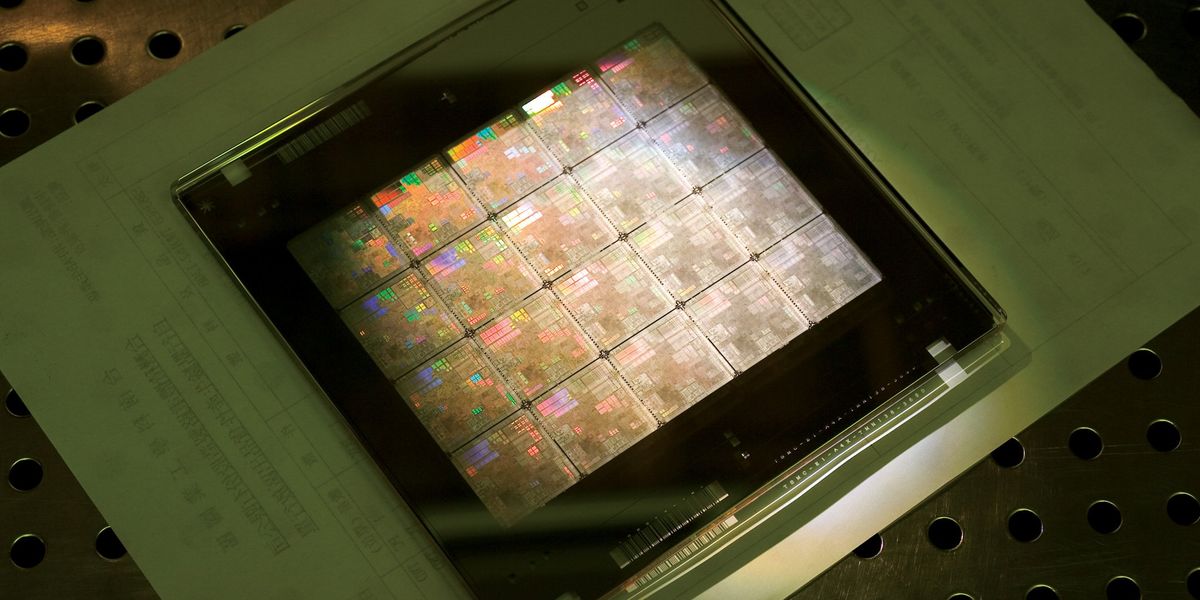

Photolithography is principally step one within the chipmaking course of. It entails bouncing gentle off of a sample known as a photomask to venture the types of transistor constructions and interconnects onto the wafer. (Extra mature expertise makes use of transmissive photomasks as an alternative of reflective ones, however the concept is similar.) It takes 98 photomasks to make an H100 GPU, Jensen mentioned. The options projected from the photomask are smaller than the wavelength of sunshine used—193 nanometers for the comparatively massive options and 13.5 nm for the finer bits. So, with out the help of tips and design guidelines—collectively known as optical proximity correction—you’d get solely a blurry mess projected onto the wafer. However with optical proximity correction, the designs on the photomask solely vaguely resemble the sample of sunshine on the chip.

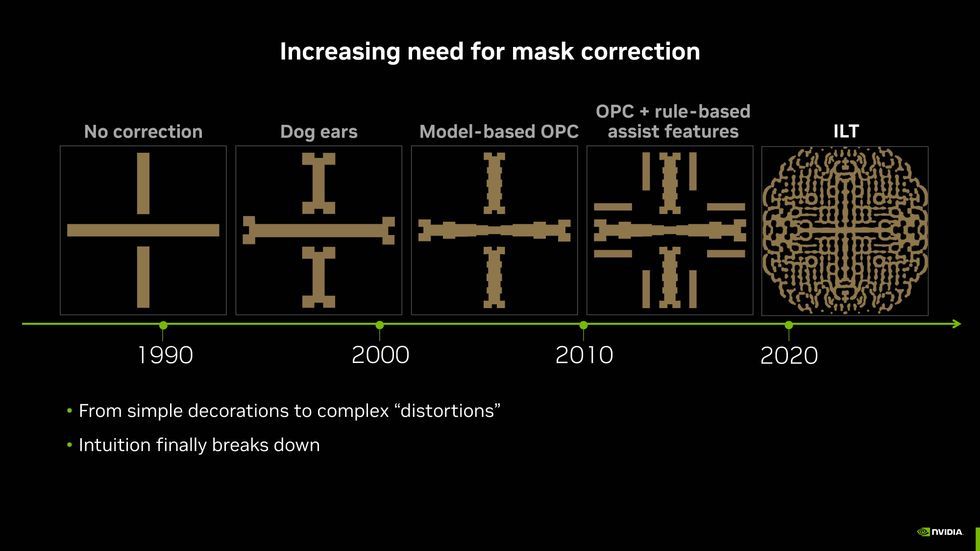

With the necessity for finer and finer options, the corrected shapes on the photomask have turn out to be increasingly more elaborate and tough to give you. It could be significantly better to start out with the sample you need on the wafer after which calculate what sample on the photomask would produce them. Such a scheme is known as inverse lithography. Easy because it sounds, it’s fairly tough to compute, usually taking weeks to compile.

In actual fact, it’s such a slog that it’s usually reserved to be used on only some crucial layers of modern chips or simply notably thorny bits of them, in line with information from the E-Beam Initiative, which periodically surveys the trade.

As chipmaking required finer and finer options, engineers needed to produce increasingly more advanced designs to venture these options onto the silicon. Inverse lithography (ILT) is the newest growth.Nvidia

As chipmaking required finer and finer options, engineers needed to produce increasingly more advanced designs to venture these options onto the silicon. Inverse lithography (ILT) is the newest growth.Nvidia

The lengthy computation time for lithography slows the event and enchancment of chip expertise Even a change to the thickness of a fabric can result in the necessity for a brand new set of photomasks, notes Vivek Ok. Singh, vice chairman within the superior expertise group engaged on silicon manufacturing at Nvidia. Computing masks “has been an extended pole in chip growth,” he says. “If inverse lithography expertise had been sped up 40 instances, would extra firms apply it to extra layers? Certainly.”

A part of the computation is a picture downside that’s a pure match for GPUs, says Singh. However at most, that may solely reduce the computation time in half. The remaining just isn’t really easy to make parallel. However over the previous 4 years, with growth companions together with TSMC, Nvidia engineers have give you a set of algorithms for making the remaining work parallel and have packaged it as a software program library to be used with GPUs.

Based on Nvidia, utilizing the cuLitho lets 500 Nvidia DGX H100 computer systems do the work of 40,000 CPU methods. It could produce three to 5 instances as many photomasks per day, drawing solely 5 megawatts as an alternative of 35 MW.

What’s extra, the expertise could ship higher outcomes, in line with Singh. CuLitho produces in any other case hard-to-calculate curvy polygons on the masks, which leads to a better depth of focus for the sample solid onto the wafer. That depth of focus ought to result in much less variation throughout the wafer and due to this fact a better yield of working chips per wafer, he says. In future, it additionally might imply fewer photomasks are wanted; with inverse lithography, what should now be carried out with a double sample would possibly work with just one.

Nvidia just isn’t the primary to look to GPUs to speed up inverse lithography expertise. Silicon Valley-based D2S introduced a GPU-based pc customized constructed for the issue in 2019. IEEE Spectrum reached out to D2S for remark, however the firm didn’t reply earlier than press time.

From Your Website Articles

Associated Articles Across the Net